|

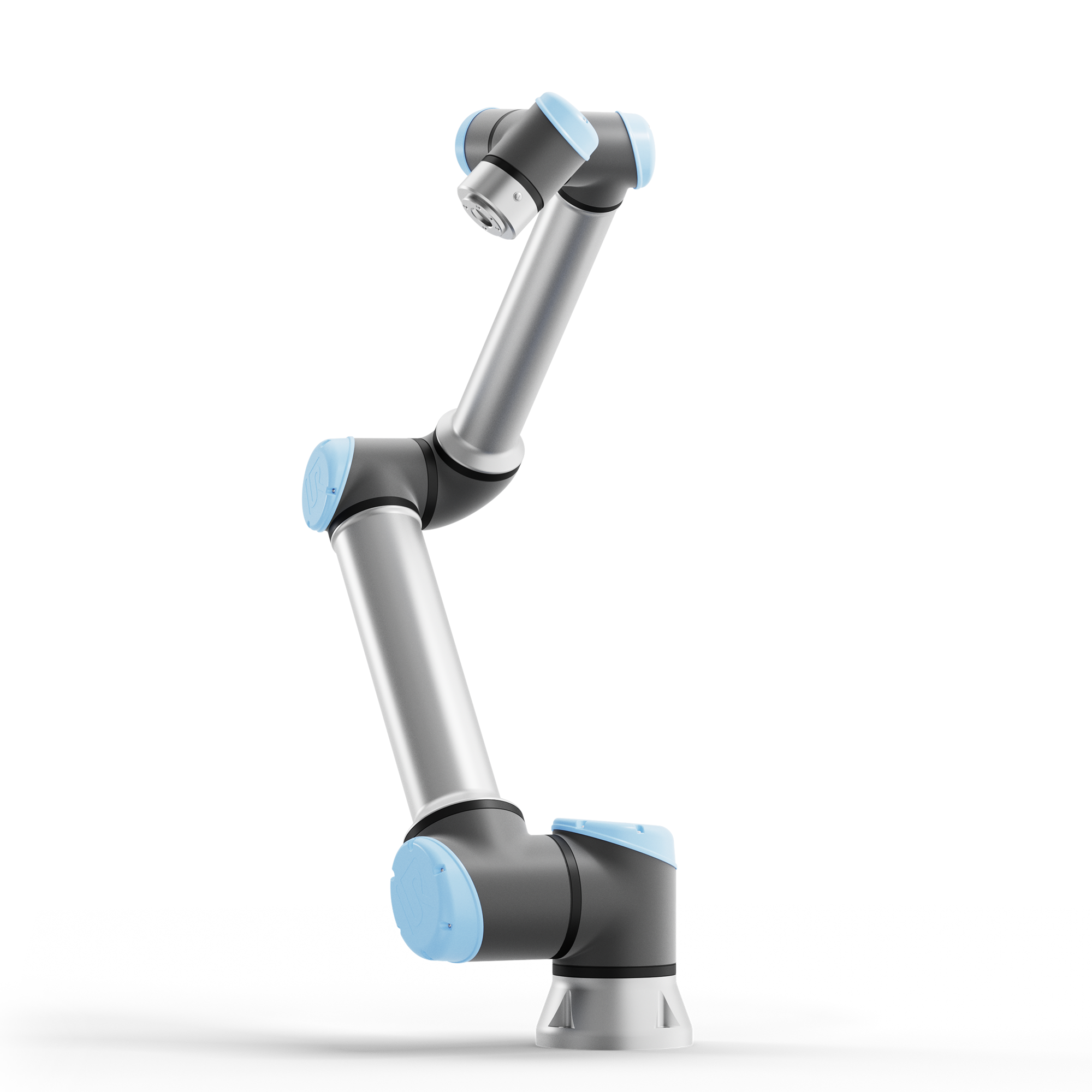

UR12e

compact cobot

|

| The UR12e is the most versatile model in our robot series, featuring a payload capacity of 12.5 kg and a working radius of 1300 mm, making it suitable for a wide range of applications. The UR12e is also available as an OEM robot system version and comes with a 3-position teaching pendant. | |

|

|

|

|

||

|

Reach |

Payload |

Footprint |

Weight |

||

| 1300 mm / 51.2 in | 12.5 kg / 27.5 lbs | Ø 190mm | 33.5 kg / 73.9 lbs |

|

|

|

|

|||||

|

Increased load capacity for palletizing applications In palletizing applications, the wrist of the collaborative robot is kept in a downward orientation, so the longer center of gravity offset allows the user to focus the robot payload more on the workpiece and less on the torque arm and gripper. In other words, palletizing applications (where the wrist is kept down) will increase payload capacity by at least 25%. |

UR Robotics has revolutionized the setup of collaborative robots. What used to take weeks to deploy a robot can now be done in a few hours. According to customer reports, their average setup time is only half a day. For an untrained operator, it takes less than an hour to unpack, install, program and realize the first simple task of a collaborative robot.

|

Don't be limited by specialized robotics. UR robots are lightweight, space-saving and easy to redeploy to multiple applications without changing the production layout. Customers can easily and quickly switch the collaborative robots to new processes and with their flexibility automate almost any job, including small batches or quick changeovers. Collaborative robots can perform repetitive tasks using the same program over and over again. |

Now you can replace operators in dirty, dangerous and boring jobs and reduce repetitive strain injuries and accidental injuries. The safety systems of our robots are approved and certified by TÜV (German Technical Inspection Association).

|

|

High payload, low energy consumption.

Energy savings with collaborative robots UR collaborative robots consume less energy than conventional industrial robots. the UR12e has an average power of 350 watts, the same as a household blender. It powers up your workflow while keeping energy consumption low. Heavy lifting With a payload of 12.5 kg and an extremely small footprint of only 190 mm in diameter, the UR12e is a robust and adaptable alternative to traditional industrial robots. The UR12e is therefore ideal for automating small workspaces. |

|

|

Increase throughput with the UR12E.

One collaborative robot - for multiple tasks One of the main advantages of UR's collaborative robots is their flexibility to be used in multiple workflows throughout a production line or facility. The same robot can even be redeployed to different applications such as palletizing, pick and place, machine tool guarding and welding. Shorter return on investment Instead of waiting years, most users of collaborative robots get a return on their investment in just a few months. |

|

UR12e Success Stories

|

|

|||||||

A 500% leap in capacity, halving labor costs, and a return on investment in three months.

DCL LOGISTICS

Brian Tu, Chief Revenue Officer, DCL Logistics, said, “The robotic system can do in two hours what a five-person team can do in a full day. The robotic system actually saves us more than 50 percent in labor costs.”

|

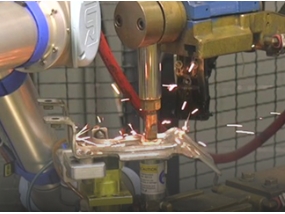

Increasing Welding Productivity and Overcoming Labor Shortages

MT SOLAR

“You can work next to the collaborative robot as it moves and welds. In the absence of safety guards, my employees can take off their shields and change parts next to it without worrying about their safety. They have become very comfortable working alongside the collaborative robot.” |

|||||||

Applications related to UR12e

|

|

|

|

|

Material Handling Packaging, Palletizing, Picking, Matching |

Welding Arc, Welding

|

Quality Inspection Testing, Inspection, Measurement

|

Reduced material manufacturing Grinding, Deburring |

UNIVERSAL ROBOTS All Models and Parameters

| Product Model | UR3/3e | UR5/5e | UR7e | UR10/10e | UR12e | UR16e | UR20 | UR30 |

| Payload | 3kg / 6.6lbs | 5kg / 11lbs | 7.5kg / 11.3lbs | 10kg / 22lbs | 12.5kg / 27.5lbs | 16kg / 35.3lbs | 25kg / 55.12lbs | 35kg / 77.16lbs |

| Effective Working Radius | 500mm/19.7in | 850mm/33.5in | 850mm/33.5in | 1300mm/51.2in | 1300mm/51.2in | 900mm/35.4in | 1750mm/68.9in | 1300mm/51.2in |

| Repeatability | ±0.1mm | ±0.1mm | ±0.1mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.1mm |

| Noise | Less than 70dB | Less than 65dB | ||||||

| Weight (with Cables) | 11.2kg | 20.6kg | 20.6kg | 33.5kg | 33.5kg | 33.1kg | 64kg | 63.5kg |

| Base Dimensions | Ø 128mm | Ø 149mm | Ø 149mm | Ø 190mm | Ø 190mm | Ø 190mm | Ø 245mm | Ø 245mm |

| Power Consumption (Average) | 90W | 150W | 150W | 250W | 250W | 350W | 500W | 300W |

| Degrees of Freedom | 6 rotational joints | |||||||

| Robot Installation | Any angle | |||||||

| IP Rating | IP54 | IP65 | ||||||

| I/O Ports (Robot) | 2×DI / DO 2×AI | |||||||

| I/O Ports (Control Box) | 16×DI / DO 2×AI / AO | |||||||

| Communication | TCP/IP 100Mbit, Modbus TCP, Profinet, EthernetlP | |||||||

| Safety | 15 advanced adjustable safety functions | 17 configurable safety functions | ||||||

| Certification |

Certified by TǔV NORD EN ISO 13849-1 PLd Category 3 EN ISO 10218-1 |

EN ISO 13849-1 PLd Category 3 EN ISO 10218-1 |

EN ISO 13849-1 PLd Category 3 EN ISO 10218-1 UL1740 |

EN ISO 13849-1 PLd Category 3 EN ISO 10218-1 |

||||