|

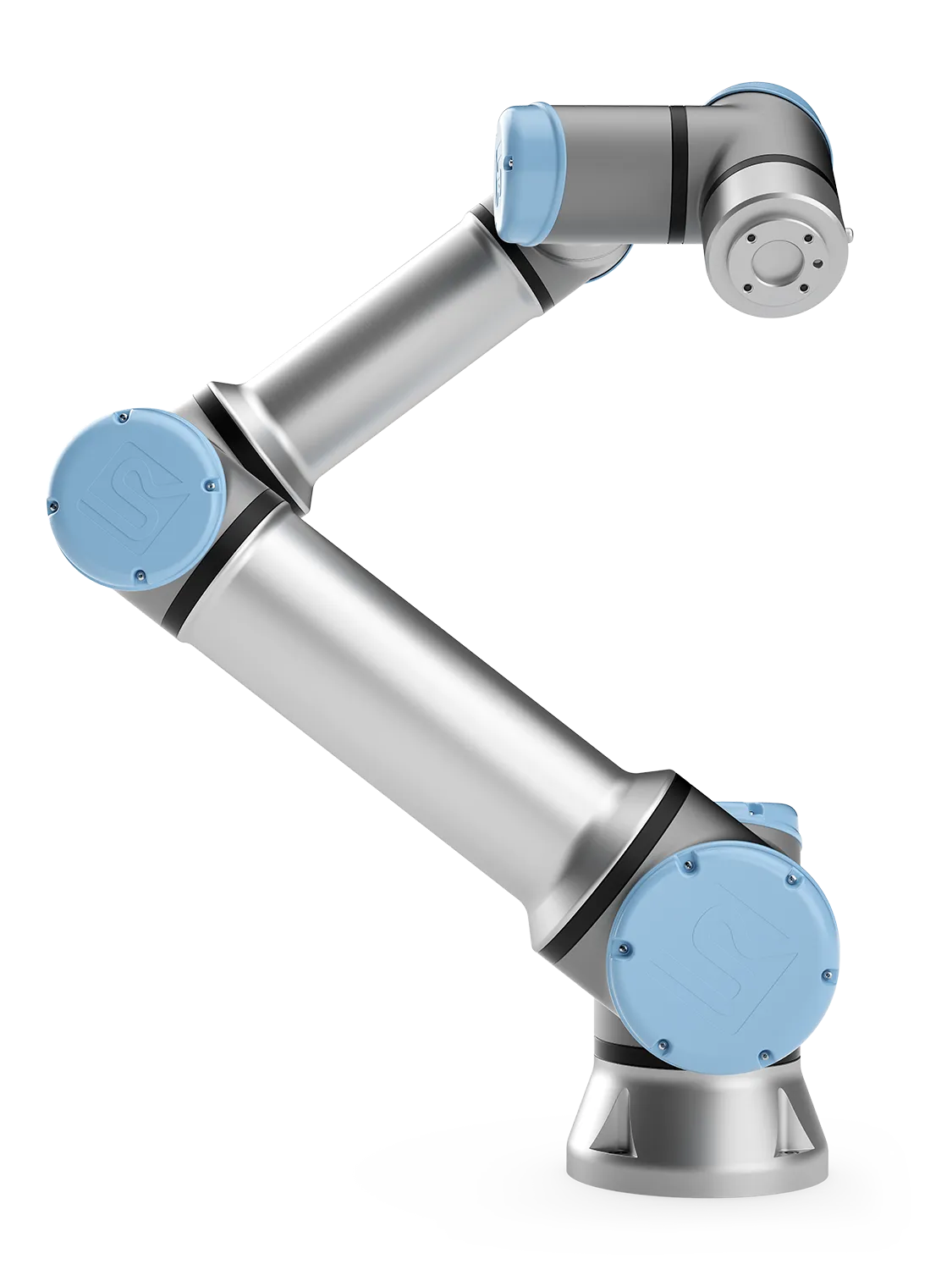

UR16e

Heavy-duty, compact cobot

|

|

The UR16e is our smaller heavy-duty industrial collaborative robot. When space is limited but you need to handle large and heavy workpieces or objects, the UR16e is the perfect choice.

|

|

|

|

|

||

|

Reach |

Payload |

Footprint |

Weight |

||

| 900 mm / 35.4 in | 16 kg / 35.3 lbs | Ø 190mm | 33.1 kg / 73 lbs |

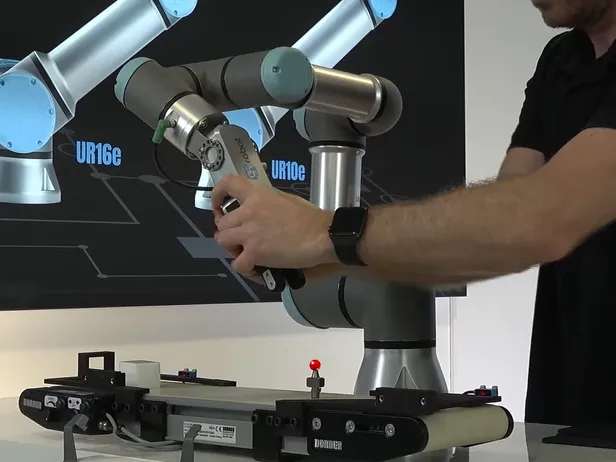

Designed for lifting

Not every job requires lifting heavy objects far or has the space for a large robotic system. The UR16e will enable you to perform heavy duty tasks like machine tending, material handling, or packaging, while fitting into smaller workspaces. Objects can be moved fast with smooth movements thanks to Advanced Motion Control.

The UR16e also comes with a suite of embedded technologies, ensuring safety when working with a collaborative, industrial robot.

|

|

|

||||

|

Possibilities Lift heavy objects in areas where space is a minimum. The combination of heavy payload but compact reach enables the UR16e to automate heavier-duty applications in tight environments. |

Productivity Increase uptime and productivity, while eliminating mistakes by introducing automated, standardized procedures.

|

Motion control Take advantage of the full speed range and accelerations while lifting the maximum payload at it's maximum reach.

|

|

What's in the box The UR16e standard order includes a UR16e robotic arm, a control box, a teach pendant (3PE is optional), a power cable and a cable between the arm and the control box, as well as documentation.

Application kits or other options are not part of the standard UR3e package and must be ordered separately.

Teach pendant By default, the UR16e is delivered with a regular teach pendant. The teach pendant contains our market leading software PolyScope to control the cobot and ensures optimal safety when working closely to the robot. A 3 position enabling devices, a so called 3PE TP, is available optional and can be purchased via UR+. Controlbox Build for any environment, the standard controlbox of the UR16e only weighs 12 kg (26.4 lbs) and offers a holders to attach the TP for optimal storage. The controller serves as the centralized hub for power, safety features, and communication, providing a compact and efficient solution for managing the operation of the UR16e system. |

|

|

|

True payload performance Future-proof your facility with a cobot which enables you to grow with your tasks. When requiring to lift heavy objects over the maximum distance, do not limit yourself by the way your end-effector is mounted. If the objects require a change of how they are being lifted, resulting a shift in the center of gravity, the UR16e will support you in this change. |

|

Safety Like every cobot made by Universal Robots, UR16e comes with built-in safety features, including force-sensing technology and collision detection. These features allow the robot to work alongside humans without the need for safety barriers or cages, increasing productivity and promoting a safe working environment.

|

|

Designed to improve your work

While our goal is to make automation available for anyone, anywhere, we also aim to support your journey in revolutionizing your business by enabling safe and collaborative human-robot interaction.

|

|

|

|

|||||

|

|

Fast deployment The out-of-box experience for an untrained operator to unpack the cobot, mount it, and program the first simple task is typically less than an hour.

|

|

Space saving Our cobot's small footprint opens opportunities to automate tasks in existing manufacturing setups where floorspace is often set and at a premium.

|

|

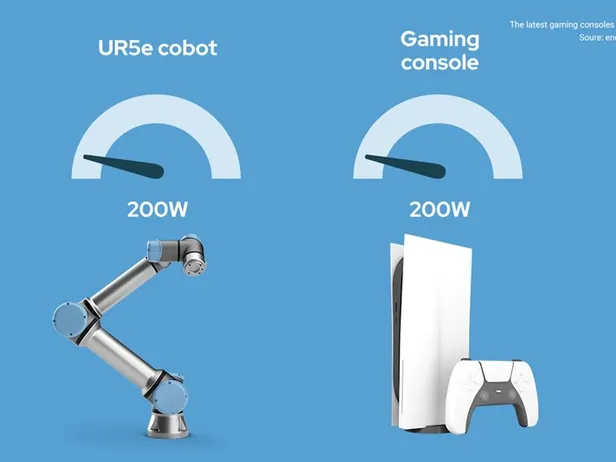

Power consumption Automating tasks gives you the possibility to run tasks autonomously without constant monitoring of your employees. In addition, UR cobots use less electricity than traditional industrial robots.

|

|

Collaborative and safe All UR cobots come with built-in safety features, including force-sensing technology and collision detection. These features allow our cobots to work alongside you without the need for safety barriers or cages, increasing productivity and promoting a safe working environment. |

|

|

Unlock the full potential of your cobot fleet By integrating your robots with our comprehensive connectivity platform, you’ll benefit from enhanced productivity, minimized downtime, and efficient fleet management – all from the convenience of your office, wherever that might be. |

Get the most out of your cobot

|

|

|

||||

|

Tool Configuration Learn how to set the tool center point (TCP), and how to adjust payload & center of gravity correctly. |

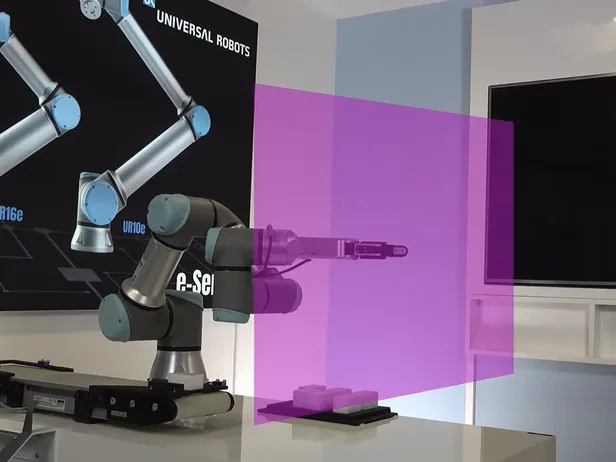

Safety planes Learn how to create and configure safety planes. A safety plane can prevent the robot from moving beyond it in normal mode, reduced mode or both; or it can trigger reduced mode. |

Learn more Visit UR Academy and browse our entire catalogue of popular topics and resources available to learn the essentials of programming a UR cobot. |

UNIVERSAL ROBOTS All Models and Parameters

| Product Model | UR3/3e | UR5/5e | UR7e | UR10/10e | UR12e | UR16e | UR20 | UR30 |

| Payload | 3kg / 6.6lbs | 5kg / 11lbs | 7.5kg / 11.3lbs | 10kg / 22lbs | 12.5kg / 27.5lbs | 16kg / 35.3lbs | 25kg / 55.12lbs | 35kg / 77.16lbs |

| Effective Working Radius | 500mm/19.7in | 850mm/33.5in | 850mm/33.5in | 1300mm/51.2in | 1300mm/51.2in | 900mm/35.4in | 1750mm/68.9in | 1300mm/51.2in |

| Repeatability | ±0.1mm | ±0.1mm | ±0.1mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.1mm |

| Noise | Less than 70dB | Less than 65dB | ||||||

| Weight (with Cables) | 11.2kg | 20.6kg | 20.6kg | 33.5kg | 33.5kg | 33.1kg | 64kg | 63.5kg |

| Base Dimensions | Ø 128mm | Ø 149mm | Ø 149mm | Ø 190mm | Ø 190mm | Ø 190mm | Ø 245mm | Ø 245mm |

| Power Consumption (Average) | 90W | 150W | 150W | 250W | 250W | 350W | 500W | 300W |

| Degrees of Freedom | 6 rotational joints | |||||||

| Robot Installation | Any angle | |||||||

| IP Rating | IP54 | IP65 | ||||||

| I/O Ports (Robot) | 2×DI / DO 2×AI | |||||||

| I/O Ports (Control Box) | 16×DI / DO 2×AI / AO | |||||||

| Communication | TCP/IP 100Mbit, Modbus TCP, Profinet, EthernetlP | |||||||

| Safety | 15 advanced adjustable safety functions | 17 configurable safety functions | ||||||

| Certification |

Certified by TǔV NORD EN ISO 13849-1 PLd Category 3 EN ISO 10218-1 |

EN ISO 13849-1 PLd Category 3 EN ISO 10218-1 |

EN ISO 13849-1 PLd Category 3 EN ISO 10218-1 UL1740 |

EN ISO 13849-1 PLd Category 3 EN ISO 10218-1 |

||||