Smarter moves, faster results

|

The MiR1200 Pallet Jack revolutionizes internal pallet transportation, automating detection, transport, and delivery of EU pallets up to 1200 kg at 1.5 m/s. Its groundbreaking AI-based perception system sets it apart, reducing pick-and-place cycle times significantly and elevating throughput. This agile robot operates continuously, with shift-long battery capacity and seamless opportunity charging for uninterrupted performance. Navigating tight spaces effortlessly, it optimizes logistics efficiency, ensuring timely pallet delivery without additional infrastructure. Perfectly integrating into various value streams, from warehouse operations to core production processes, the MiR1200 Pallet Jack is designed to comply with the safety standards. It safely navigate around people and other obstacles and constitutes a safe alternative to traditional forklifts and pallet trucks. With user-friendly software and quick scaling through MiR Fleet, deploying and managing this solution is straightforward, making it the ultimate blend of precision, performance, and productivity. |

√ AI-based perception for fast, precise and reliable pallet detection √ High battery-capacity and fast charging for working in 24/7 workflows √ Designed to comply with present safety standards -ISO3691-4 |

|

Pallet Detection The MiR1200 Pallet Jack utilizes machine learning perception to detect pallets, enabling the recognition of shrink-wrapped pallets with rapid, precise, and reliable detection. |

||

|

Safety The MiR1200 Pallet Jack designed to comply with ISO3691-4 safety standard and offers comprehensive 360-degree safety coverage.lt detects and avoids obstacles up to the full height of the robot. |

||

|

Signal Lights The MiR1200 Pallet Jack uses signal lights to indicate its actions to people working around it. This makes it easy for those in proximity to understand the robot's direction and activities |

||

|

Battery Capacity Featuring a high battery capacity and fast charging capability, the MiR1200 Pallet Jack ensures seamless operation in 24/7 workflows. |

||

|

Ease of use The MiR1200 Pallet Jack is equipped with MiR's latest software. lt seamlessly integrates with MiR Fleet alongside other MiR robots. |

| Realize improved efficiency | Get fast throughput | Enhance workplace safety | Optimize your entire value chain | Run 24/7 workflows | ||||

| Move up to 1200 kg pallets automatically | With AI-based pallet perception for fast pallet detection | Replace your manual forklifts with the safest AMR Pallet Jack | With a wide range of AMRs from MiR, all controlled by MiR Fleet | Thanks to fast charging and high battery capacity |

| Designated use |

Autonomous mobile robot (AMR) for automated driverless conveyance of heavy loads |

|

| Type | Autonomous Mobile Robot (AMR) | |

| Color | RAL 7011 / Iron Gray | |

| Product design life | 5 years or 20 000 hours of active operation, whichever comes first | |

| Length | 1934 mm / 76.14 in | |

| Width | 800 mm / 31.5 in | |

| Height | 2130 mm / 83.86 in | |

| Weight | 810 kg / 1786 lbs | |

| Maximum lift height | 1140 mm / 44.9 in | |

| Maximum payload | 1200 kg / 2646 lbs | |

|

Maximum speed (with maximum payload on a flat surface) |

1.5 m/s (5.4 km/h) | 4.9 ft/s (3.6 mph) | |

| Maximum dB emitted from the robot | 77.3 dB | |

| Time used when picking up and placing pallets |

From front Entry position: Up to 40 s pick up time and up to 30 s place time From right or left Entry positions: Up to 55 s pick up time and up to 50 s place time |

|

|

Space requirements:Operational corridor width ¹ |

At full speed: 2350 mm / 92.5 in At reduced speed: 1600 mm / 63 in |

|

|

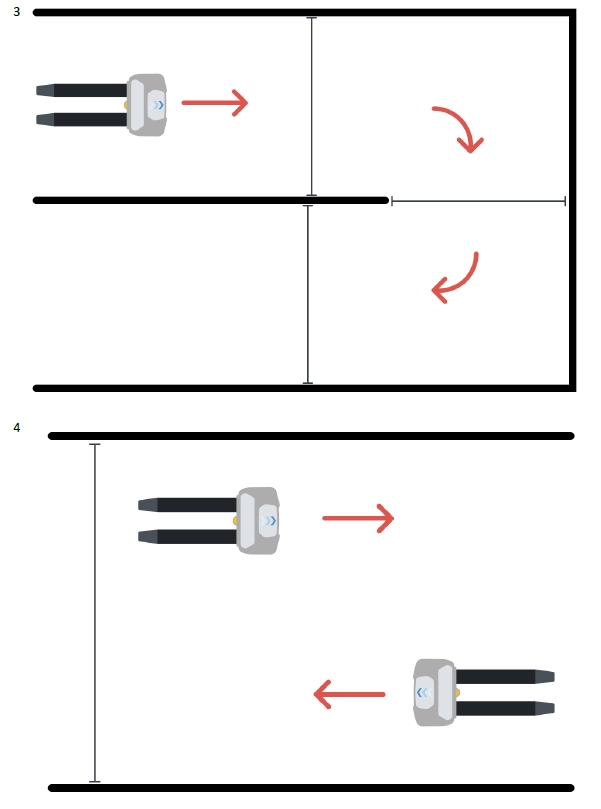

Space requirements:Operational corridor width for a 90°turn ² |

2000 mm / 78.7 in | |

|

Space requirements:Operational corridor width for a U-turn ³ |

Without pallet: 1950 mm / 76.8 in With pallet: 2050 mm / 80.7 in |

|

|

Space requirements:Operational corridor width for two robots passing ⁴ |

At maximum speed: 4700 mm / 185.1 in At reduced speed: 3200 mm / 126 in |

|

| Battery type | Lithium-ion, 3 pcs | |

| Battery weight | 11 kg | 24.3 lbs (each battery) | |

| Battery voltage | 48 V nominal | |

|

Active operation time with maximum payload |

Up to 10 h | |

| Environment | For indoor use only | |

| Ambient temperature range, operation | 5–25 / 41–77°F, 40°C / 104°F for up to 1 hour | |

| Humidity | 20–95% non-condensing | |

| IP rating | IP 52 | |

| Floor to wheel frictional coefficient | Minimum 0.60 | |

|

Designed to meet safety standards for industrial vehicles |

EN ISO 12100:2010, ISO 13849-1:2023, EN ISO 13850:2015, EN ISO 3691-4:2023, EN IEC 61000-6-4:2007/A1:2011, EN IEC 61000-6-2:2005/AC:2005, EN 12895:2015+A1:2019 |

|

| Sensors:SICK safety laser scanners | 3 pcs (front and rear), give 360° visual protection around the robot | |

| Sensors:3D cameras | 5 pcs, For pallet and obstacle detection | |

| Sensors:3D LiDAR | 1 pcs, on top of the robot | |

| Sensors:Ultrasonic sensor | 1 pcs, For detecting pallets are securely placed on the forks |