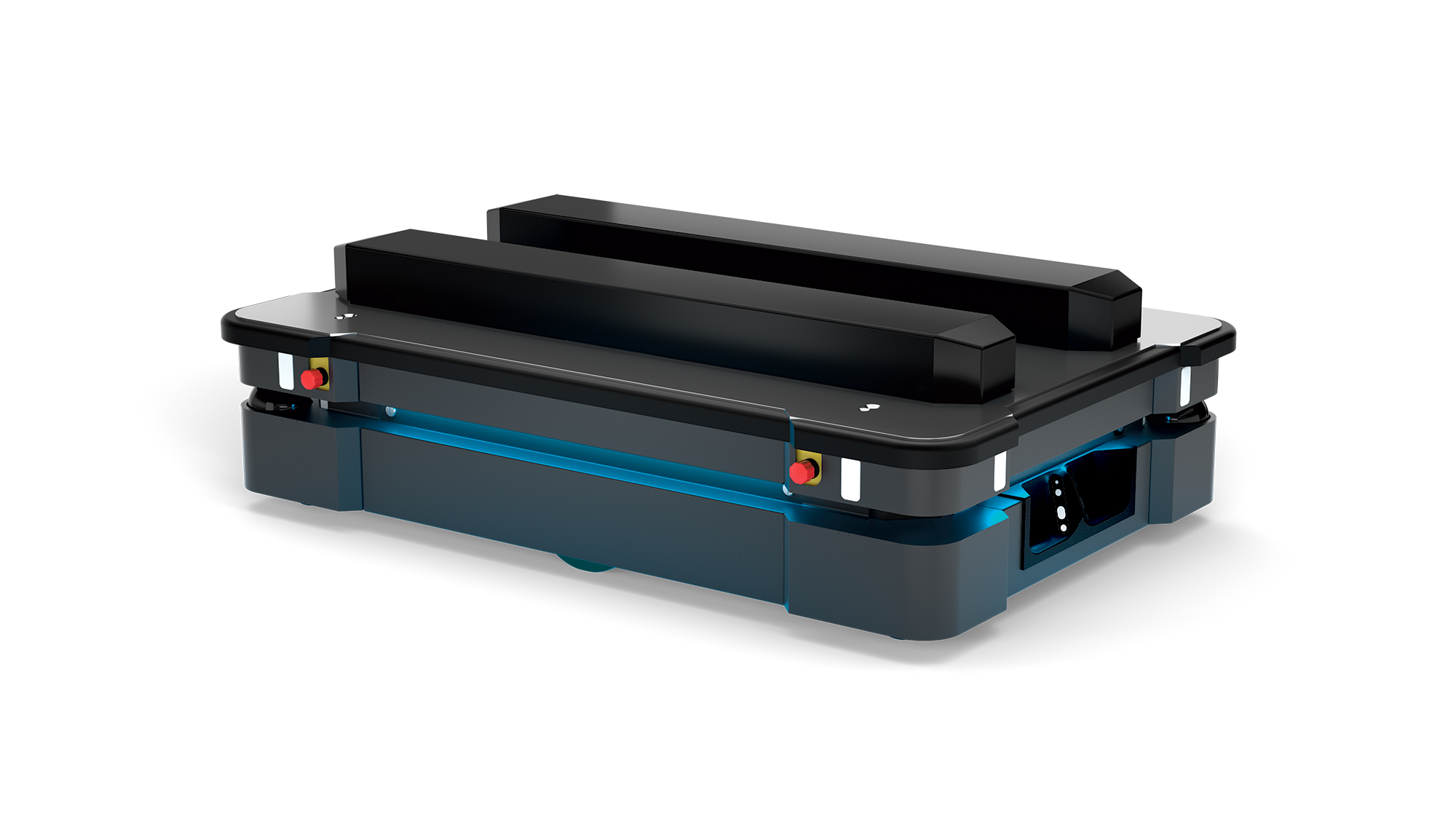

MiR500 is designed for automatic transportation of pallets and heavy loads in various industries. With a load of 500kg, a maximum speed of 2m/s, and a length and width of 1350x920mm, MiR's MiR500 is a collaborative autonomous mobile robot with large size, strong lifting ability, fast operating speed, and robust design.

Safe and efficient transportation

The collaborative MiR500 can safely shuttle between personnel and physical obstacles. With advanced technology and complex software, the robot is able to automatically navigate and detect reasonable routes to its destination. When encountering obstacles, the robot will automatically re plan its route to avoid costly backlogs in the logistics process.

The MiR500 is equipped with advanced laser scanning technology that provides a 360 degree scanning angle, ensuring optimized safety. The 3D camera of MiR500 can detect trays with a scanning range of 3cm to 2 meters on the ground. In addition, the robot can also recognize and avoid potholes on the ground.

Optimize pallet transportation without changing factory layout

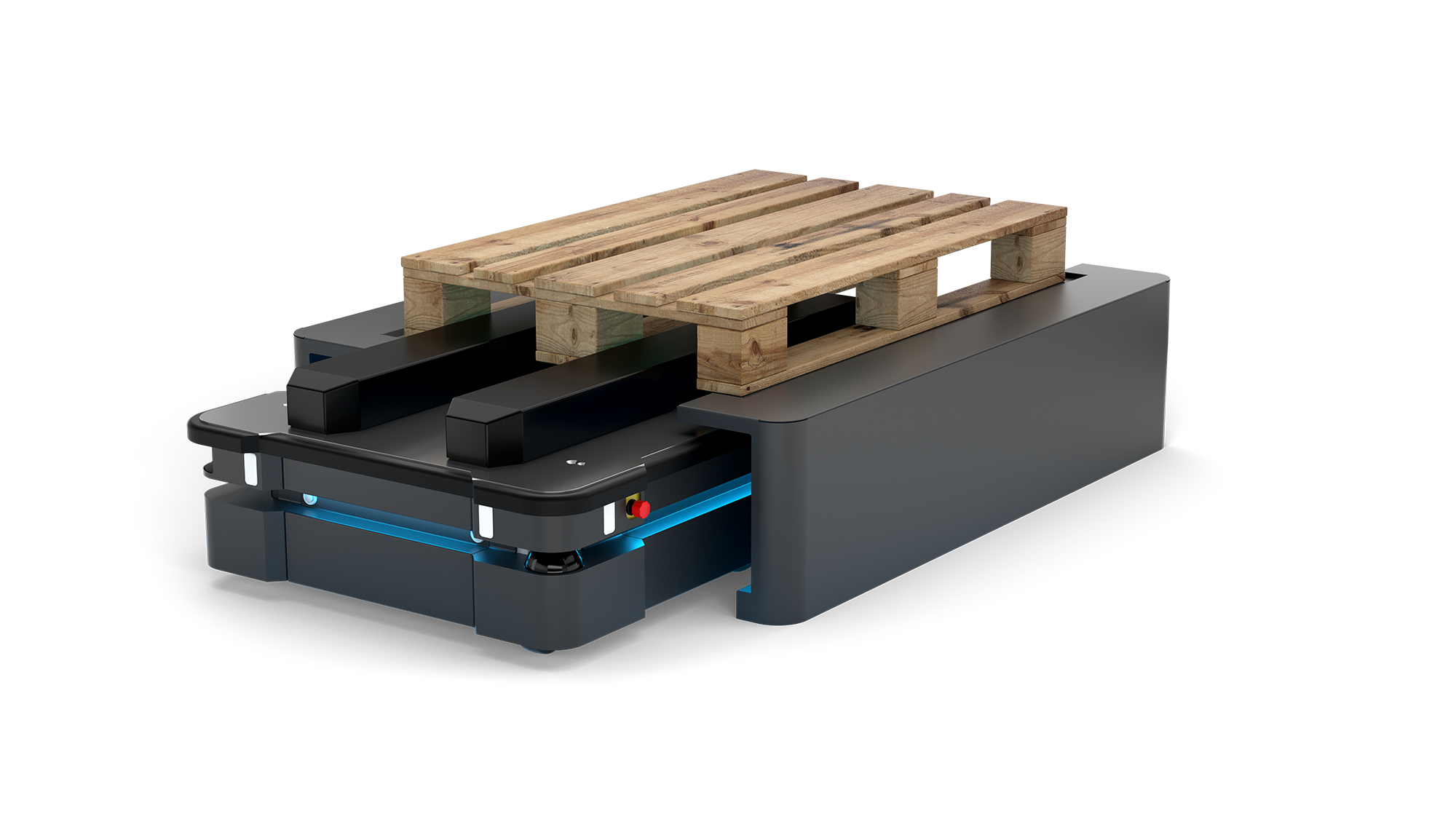

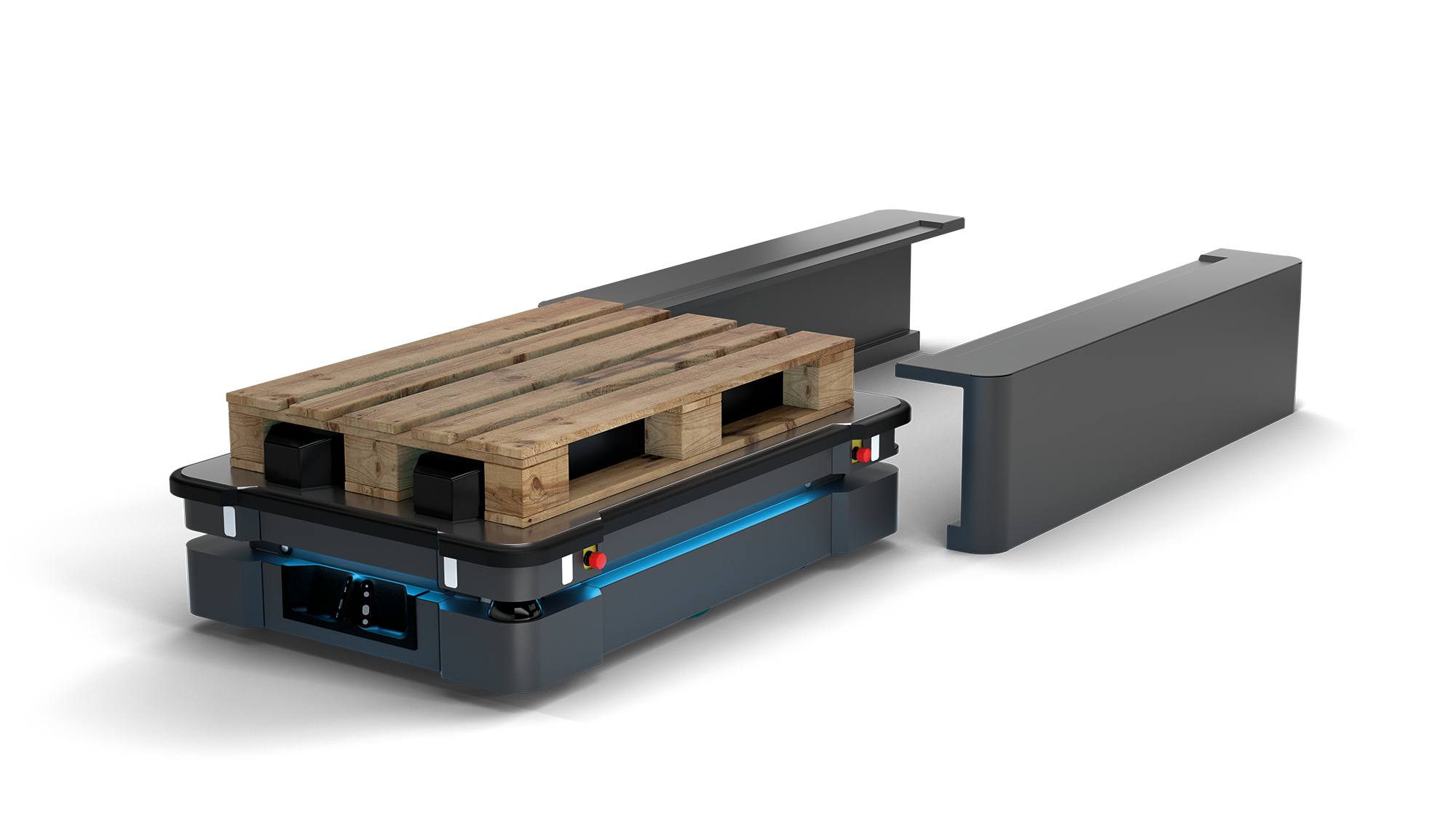

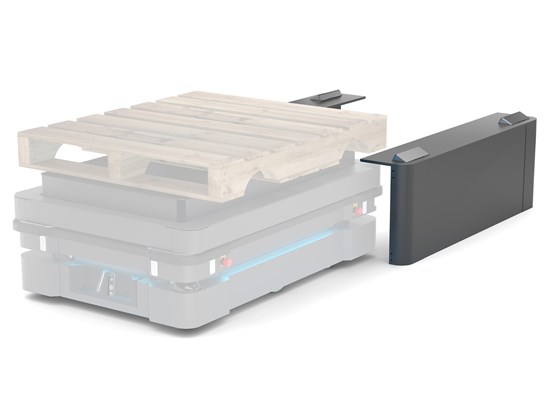

With the help of the MiR500 pallet lift, the MiR500 can automatically pick up, transport, and unload pallets, freeing up labor for businesses to complete more valuable tasks. You only need to download the CAD files of the factory to the robot, or use its laser scanner to create a factory map, and the robot can achieve automatic navigation, ensuring fast and cost-effective implementation of automated transportation processes for you.

Robust robots designed for industrial applications

MiR500 meets the ISO/EN 13849 standard and complies with EMC requirements for heavy and light industrial environments. MiR500 is designed specifically for industrial applications: its exterior components have been further optimized and enhanced to effectively protect goods (such as preventing them from falling off) when passing through bumpy roads or small puddles.

Highly user-friendly and flexible

MiR500 provides a high level of user friendliness at all levels, allowing you to have full control from the beginning. You can control the MiR500 through an intuitive MiR robot interface on your smartphone, tablet, or PC without any programming background. This robot can also be integrated into an ERP system for you to create fully automated solutions.

In addition, the integration of various top modules of the robot is also very simple and fast. MiR500 can easily configure pallet forks, conveyors, robotic arms, or any other device.

✓Easily and cost efficiently create automated pallet internal transportation solutions.

✓Achieve extremely stable and safe pallet transportation in highly dynamic environments

✓Existing facilities do not require any modifications

| Collaborative Mobile Robots | Used for lightweight transportation tasks in industrial, logistics, and medical facilities |

| Length | 1350 mm |

| Width | 920 mm |

| Height | 320 mm |

| Ground clearance | 30 mm |

| Weight(No load) | 414 mm |

| Load surface | 1300 x 900 mm |

| Height with MiR500 EU lifting tray | 407 mm |

| Height with MiR500 lifting tray | 414 mm |

| Weight with MiR500 EU lifting tray | 300 kg |

| Weight with MiR500 lifting tray | 342 kg |

| RAL 7011 | Iron Gray |

| Maximum payload | 500 kg / 1100 lbs |

| Battery running time | 8 h |

| Maximum speed | 2.0 m/s (7.2 km/h) |

| Rotation radius | 2000 mm |

| VL Marking accuracy | Location (robot center):+/-5/ 0.2"。angle:+/- 1˚ |

| battery | Li-NMC, 48 V, 40 Ah |

| charging time | MiR Charge:1 h(10% ~ 90%);Wired charger:2 h(10% ~ 90%) |

| External charger | Input:100-230 V ac,50-60 Hz / output:48 V,maximum 40 A |

| Number of battery charging cycles | At least 700 times |

| Ambient temperature range | +5°C ~ 40°C(Humidity 10 ~ 95%, non-condensing) |

| IP rating | IP 21 |

| authentication | 5 types of safety functions, compliant with ISO 13849-1, standard:ISO/CD 3691-4, EN1525, ANSI B56.5 |

| EMC | EN12895, EN61000-6-2, EN61000-6-4 |

| WiFi | Dual band wireless AC/G/N/B |

| I/O | 6 digital input ports, 6 digital output ports, and 1 Ethernet port supporting Modbus protocol |

| SICK microScan3(2 pcs) | Provide 360 ° visual protection for robots |

| 3D cameras(2 pcs) | 2 pcs:Intel RealSense D435。 Field of view: Objects with a height of 1700 mm can be detected 950 mm in front of the robot. 114 ° overall horizontal view. Ground view, minimum distance from robot: 250 mm |

| Distance Sensor | 8 pcs |

| タイプ | 協働型モバイルロボット |

| 用途 | 荷物の内部輸送、内部物流の自動化 |

| 色 | RAL 7011 / アイアングレー |