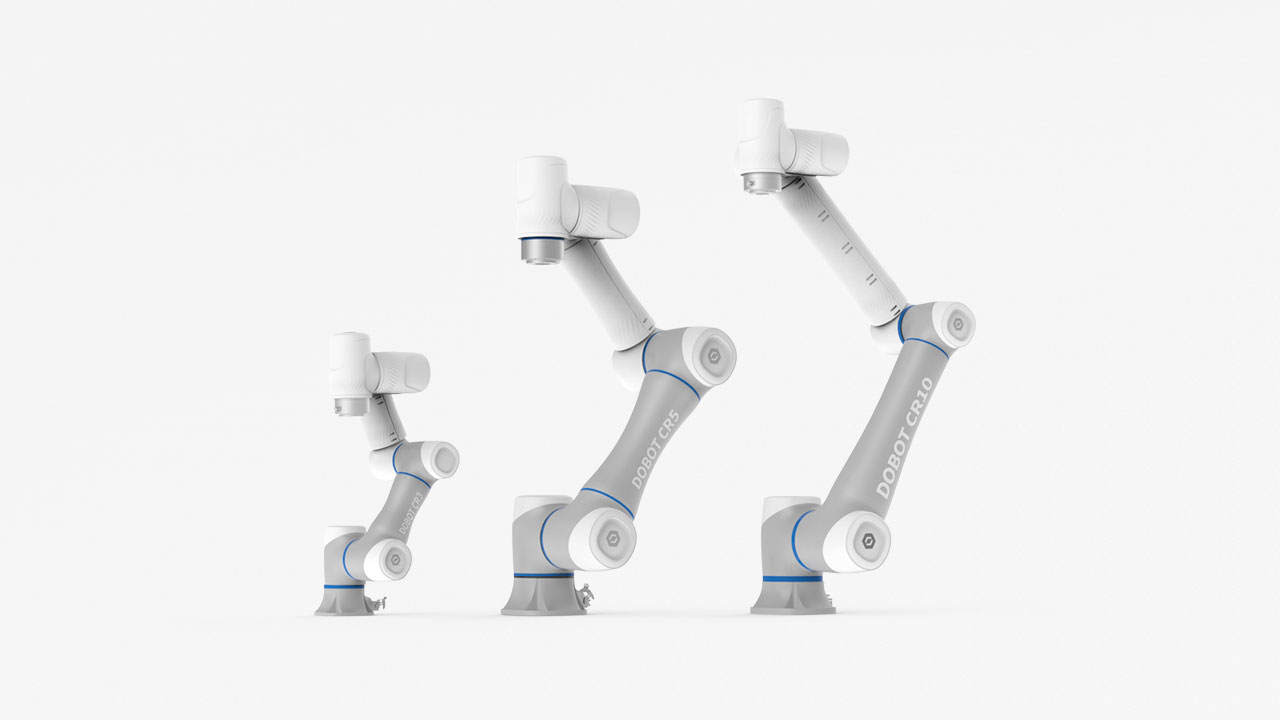

The CRS series collaborative robot is an upgraded version of the CR series collaborative robot, which adds the DOBOT safety skin non-contact collision detection solution and has unparalleled safety. At the same time, it continues the advantages of the previous generation product, such as flexibility, easy deployment, and high precision. At present, the CRS series is designed with three types of loads: 3 kg, 5 kg, and 10 kg, suitable for multiple industries such as automotive, 3C, and home appliances. Especially in human-machine collaboration scenarios, it can better meet the needs of customers for both safety and efficiency.

|

FEATURES AND BENEFITS

DOBOT self-developed pre collision sensing technology is contactless and safer!

The CRS series is equipped with DOBOT self-developed technology - flexible safety skin, which achieves active safety protection through non-contact collision detection technology, maximizing the safety and operational efficiency of human-machine cooperation.

Unlike traditional collaborative robots that detect collisions and stop, robots with safety skins can perceive objects within 15 cm and achieve safe shutdown without contact between the robot and the human body, greatly improving the safety of human-machine collaboration and ensuring safety even during high-speed movements.

Under the protection of safe skin, the robot does not need to give advance warning to slow down, and can increase the human-machine cooperation speed from 0.25 m/s to 1m/s, increasing the human-machine cooperation efficiency by 4 times.

The CRS series provides three programming methods: graphical programming, demonstration reproduction, and script programming, which are suitable for use by personnel at different stages. Through rich plug and play ecosystem components and process package support, applications such as loading and unloading, assembly, gluing, polishing, etc. can be quickly integrated, and even more intelligent flexible automation solutions such as disorderly sorting and dynamic screwing can be easily created.

Application scenarios Screw lock attachment, palletizing

|

|

Empowering the entire industry

Committed to providing automation and intelligent upgrade solutions for various industries such as automotive parts, 3C electronics, metal processing, food packaging, medical health, and new retail.

DOBOT CRS series All models and parameters

| Product Name | CR3S | CR5S | CR10S |

| Weight | 16.5kg | 25kg | 40kg |

| Rated load | 3kg | 5kg | 10kg |

| Working radius | 620mm | 900mm | 1300mm |

| Repetitive positioning accuracy | ±0.02mm | ±0.03mm | |

| Maximum straight-line velocity | 2m/s | ||

| Joint range of motion | ±155° - ±360° | ±160° - ±360° | |

| Maximum joint velocity | 180°/s - 223°/s | 150°/s - 223°/s | |

| End I/O |

DI/DO/AI:2 RS485:support |

||

| IP rating | IP54 | ||

| Noise | 70dB(A) | ||

| Temperature range | 0℃ -45℃ | ||

| Typical power consumption | 120W | 150W | 350W |

| texture of material | Aluminum alloy, ABS plastic | ||

| Installation method | arbitrary | ||

| Flexible electronic skin | have | ||