Fast, accurate, stable benchmark, industry-leading sports performance

|

FEATURES AND BENEFITS

Each robot is precisely calibrated using a laser tracker, with a positioning accuracy of less than 0.4mm, making it easy to handle more high-precision production tasks and providing better consistency and quality assurance for production.

Adopting a new generation of independent safety controllers that comply with PLd Cat.3 level, with over 20 safety functions, and certified with safety certifications such as ISO 13849-1, ISO 10218-1, and ISO/TS 15066. After risk assessment, there is no need to add fences to cooperate with people and meet strict safety standards.

When the robot encounters an unexpected power outage, it can quickly brake within 18ms and maintain its position within 1mm, effectively preventing equipment or product damage caused by unexpected power outages.

Providing virtual fence function and advanced non-contact safety skin, users can develop more suitable safety strategies based on the actual production environment to maximize safety production.

The number of universal interfaces DI and DO has been expanded to 24, supporting PNP and NPN switching, and can be configured with over 30 robot control and status feedback functions, providing more convenience and flexibility for equipment integration and control in the field of industrial automation. Standard configuration includes multiple communication methods such as Modbus TCP/RTU, EtherNet/IP, PROFINET, etc., making it easy to connect to mainstream PLC, HMI and other devices without worrying about communication protocol compatibility, making device integration and configuration more efficient and convenient.

Pre collision perception enables robots to achieve both safety and efficiency improvements.

Easy to use and enjoy high efficiency.

|

|

Empowering the entire industry

Committed to providing automation and intelligent upgrade solutions for various industries such as automotive parts, 3C electronics, metal processing, food packaging, medical health, and new retail.

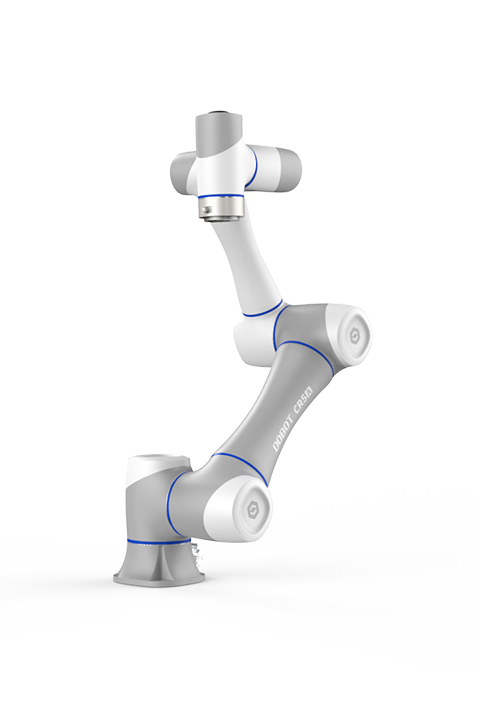

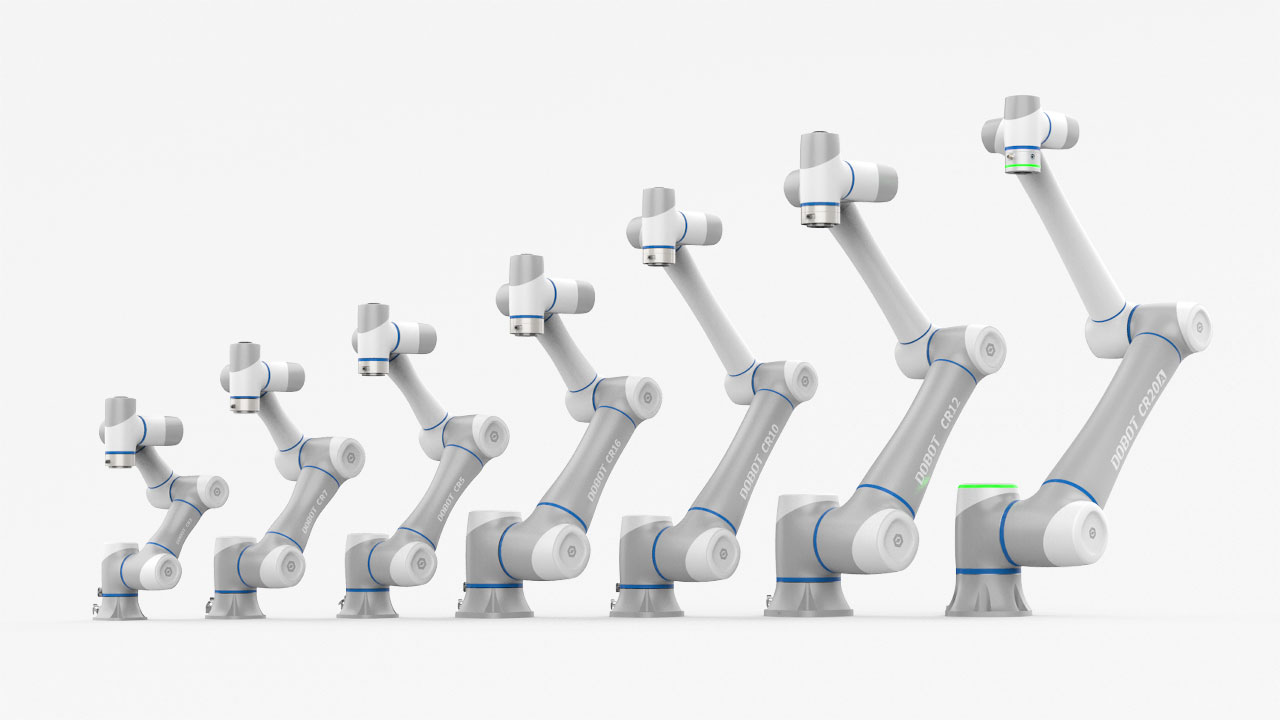

DOBOT CRA series All models and parameters

| Product Name | CR3A | CR5A | CR7A | CR10A | CR12A | CR16A | CR20A |

| Weight | 16.5kg | 25kg | 24.5kg | 40kg | 39.5kg | 40kg | 70kg |

| Rated load | 3kg | 5kg | 7kg | 10kg | 12kg | 16kg | 20kg |

| Working radius | 620mm | 900mm | 800mm | 1300mm | 1200mm | 1000mm | 1700mm |

| Repetitive positioning accuracy | ±0.02mm | ±0.03mm | ±0.1mm | ||||

| Maximum straight-line velocity | 2m/s | ||||||

| Joint range of motion | ±155° - ±360° | ±160° - ±360° | ±165° - ±360° | ||||

| Maximum joint velocity | 180°/s - 223°/s | 150°/s - 223°/s | 120°/s - 180°/s | ||||

| End I/O |

DI/DO/AI:2 RS485:support |

DI/DO/AI:4 RS485:support |

|||||

| IP rating | IP54 | ||||||

| Noise | 70dB(A) | ||||||

| Temperature range | 0℃ -50℃ | ||||||

| Typical power consumption | 120W | 150W | 350W | 50W | |||

| texture of material | Aluminum alloy, ABS plastic | ||||||

| Installation method | any | ||||||