|

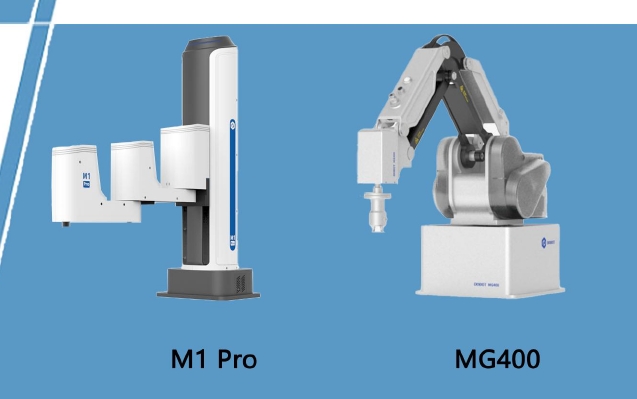

About DOBOT M1 ProM1 Pro continues the advantages of high precision, wide range, complete functions, and support for secondary development of the previous generation SCARA collaborative M1 product. At the same time, it integrates the intelligent software and hardware platform of the forefront of DOBOT technology, which is very suitable for intelligent manufacturing processes in the light industry field and capable of handling more complex process sites.

FEATURES AND BENEFITS

The embedded integrated whole machine design of the electrical control cabinet eliminate wiring and routing troubles. Plug and play simple installation method, greatly saving connection and installation time.

Provide programming methods such as graphical and scripting. Supports wired or wireless connection to mobile phones PAD、 Multiple operating terminals such as computers, easy to operate and learn.

The M1 Pro comes with collision detection and safety protection functions, allowing for worry free collaboration with humans. The forearm is 40% narrower than traditional industrial robotic arms, effectively reducing accidental collisions and damage to the machine.

Add a quantitative differential encoder interface to expand dynamic capture and tracking applications. Support parallel processing such as multithreading and IO control during motion, effectively shortening the robot's movement rhythm.

Related Cases

Visual inspection of electronic control board, sorting of 3C components, beverage vending machine |

|

|

About DOBOT MG400DOBOT MG400 is an industrial grade desktop four axis collaborative robot, with a base that occupies a smaller area than A4 paper. Featuring flexibility, ease of deployment, simplicity, and secure collaboration, it is designed specifically for the diverse and small-scale automation production needs. With a maximum load of 750 g and a 440 mm arm length, the MG400 fully meets the requirements of lightweight desktop applications. Its human-machine collaboration features such as drag and drop teaching and collision detection enable it to truly meet the rapid deployment requirements of production lines. It is a cost-effective choice for automated and intelligent production.

FEATURES AND BENEFITS

To fully utilize the production space and easily integrate into the existing production environment, MG400 adopts a compact design that integrates the controller and body. The base area is only 190mm X 190mm, which can accommodate A4 paper space for deployment.。

The MG400 adopts a servo motor with a high-precision absolute encoder, combined with independently developed servo drive and controller, which can achieve a repeat positioning accuracy of ± 0.05 mm. By using the controller vibration suppression algorithm, while ensuring the accuracy of the robot's multi axis linkage spatial trajectory, the bandwidth stability time of repeated positioning accuracy is accelerated by 60% and residual vibration is reduced by 70%.

Simple design concepts are integrated into every dimension of robots, fully reducing the difficulty of automation import for small and medium-sized enterprises.

Integrated compact design, flexible and easy to deploy, plug and play.

The three programming methods of demonstration reproduction, graphical programming, and Lua script programming are suitable for applications of different complexities and programming developers of different skill levels.

Combined with the robot power compensation algorithm, the drag teaching is lightweight and smooth, which can reduce the point teaching time during robot debugging by more than 80%.

Related Cases

Cleaning and loading/unloading of projector aluminum sheets, loading/unloading of assembly line trays, automation plugin for air conditioning motherboards

|

Model and parameters

| Product Name | M1 Pro | MG400 |

| Weight | 15.7kg | 8kg |

| Rated load | 1.5kg |

500 g(Max. 750g) |

| Working radius | 400mm | 440mm |

| Repetitive positioning accuracy | ±0.02mm | ±0.05mm |

| Maximum working speed | 2m/s | / |

| Joint range of motion | ±85° ~ ±130° | -25° ~ ±360° |

| Maximum joint velocity | 180°/s | 300°/s |

| End I/O |

16 digital outputs |

/ |

| Temperature range | / | 0℃ - 40℃ |

| Typical power consumption | / | 150W |

| Communication method | TCP/IP,Modbus TCP software | |

| Base size | / | 190mm ×190mm |

| Installation method | / | Desktop installation |

| Power Supply |

100~240VAC 50/60Hz |

|